Have a seat and grab a beer...

As we approach the months of March and April 2017 and we near the anniversary

of our new facility opening, we’re finally able to turn around and view some of the landscape we’ve trekked over the past year. The last

twelve months have been an unbelievable roller coaster of success, chaos, and rebuilding.

Some businesses make it look easy, and to those viewing Red River Brewing from the periphery, it can seem like all is well so long as the product is available on the shelf

and at the tap. We hear from people daily that say "man, y'all's beer is everywhere!". It's true, we've come a long way since the early days. One thing has been constant while building our brewery, we’ve learned that the word “easy”

is not something that seems to find us often.

(That's me on the far left and Beau on the far right at our ground breaking ceremony in September of 2015. I'm the guy getting out-sholved handily by two women.)

For those that don't know much about our brand and our story, we started our brewery in my garage (sigh, yes that idyllic) around 2010. We were the three crazy homebrewers who actually lobbed our snowball that quickly made its parabolic arc towards hell.

A few people tried to stop us (our wives), and many others egged us on (mainly other crazy homebrewers). We did have some practical approaches to starting out in an industry we knew little about and had zero experience in. The idea of a massive operation scared the hell out of us (rightfully so considering we'd never made more than 15 gallons of beer at a time before going pro), so we started small. A five-barrel brewhouse, and we'd only package our beer in kegs. Come to find out, draft beer (beer in kegs), and especially craft, draft beer is a really small market in Shreveport/Bossier. Like less-than-3%-of-the-local-market small.

Ignorant to these facts, we started producing our beer commercially in October of 2013. The three of us - Robert McGuire, Beau Raines, and me - kept our day jobs, and we decided we'd run our brewery on the weekends until we could grow it into a big enough operation to sustain an actual job or two. Little did we know that this "weekend brewery" actually meant brewing for 22 hours straight every other weekend. For two years. This also meant spending at least 4-5 hours at night after work, if not two or three nights some weeks, kegging or cleaning or prepping brews or cleaning or raising money or cleaning. Did I say cleaning? Needless to say, there was nothing "weekend" or "part-time" about it. A couple of us might have had a kid or two while this madness was going on as well. Our wives would tell you our kids were fatherless during this time and they're only about 100% correct. But hey, what's a little more responsibility and lost sleep thrown in with an already poorly thought-out situation?

We always thought that if we could just get into a bigger facility, with a bigger brewhouse and a bottling line...and a (ooohhh) taproom, that things would become much easier. We'd crest the hump and we'd be able to coast downhill with our feet on the handle bars. We're still waiting for that day, btw.

After enough follies to make a government agency blush, we finally moved into our new digs at 1200 Marshall Street in downtown Shreveport in late March of 2016 (we'll dive deeper into the hoopla of that in an upcoming news article). We'd bought a bigger brewhouse, bottling line, hired a great team, and built a taproom that could have swallowed our original brewery 4 times over. All was going to be great now. We were finally going to be able to put our beers into

bottles and bring them to consumer’s refrigerators. But true to form for our company, this feat of

industrial marvel required no less than the utilization of three different bottling machines…all during the first 60 days of

getting our beers bottled.

"Packaging" as we call it at Red River Brewing Company, is a term commonly used in the beer industry. This just means bottling. During our two years of just kegging our beer, we'd built up an idea that "bottling" would resemble something as beautiful and as fluid as Natalie Portman playing a ballerina in that really weird movie that I still don't quite understand. In reality, packaging is more like child birth or trying to remove your kids from a Chucky Cheese. There's crying and swearing, there's fluids on the floor, and you're just ready for it to be over.

The machine we originally purchased

(finally) arrived in mid-May of last year and was only about 10 weeks late. This filler/crowner (another cool beer industry term that just means a bottling machine) was a prototype from a reputable manufacturer that we thought was going instantly make us the next cool-kid-brewery success story.

Imagine yourself after three years of build-up and anticipation. When the big day finally arrives, you show up to the christening and

the champagne bottle knocks a hole in the stern and the entire ship sinks in front

of you. Oh, and there's a rope tied to your ankle that's connected to the ship that pulls you in the ocean, too. And your wife, your kids, your partners, and their kids and their wives as well.

The reason we selected this machine was its (alleged)

ability to allow us to use three different bottles sizes and types. Imagine Hay Ryed in 10 ounce pony bottles, right? In the end,

we would have settled for one bottle size that actually worked. After four

days of anguish and trying to put the liquid into a bottle and put a lid on it,

both parties agreed the machine wasn’t yet sea worthy. During the good runs, we were cranking out

seven bottles per minute, and that's when the caps actually stayed on. To give you a

bit of perspective of this massive inefficiency, we can run our current filler/crowner at nearly six times that fast. When she's completely dialed in, she can fill roughly 40 bottles per minute.

Thankfully, the folks at Flying Heart Brewing across the river from us allowed us to utilize their Meheen bottler....I mean filler/crowner. By some type of divine

intervention, both breweries had somehow chosen exactly the same bottle type and bottle size. Flying Heart was able to allow us to utilize their machine during their

down time, and without this gracious act, we were effectively “bottle necked”

from a production standpoint. Our tanks were completely full of beer, and we had no way of making more beer without getting it into bottles. Remember the stats on draft beer in our market listed above? 400 kegs of beer wasn't going to find it's way to Joe Q. Baptist's gullet anytime soon without the discretion of being able to drink it home. Bottle beer sells well in grocery stores, liquor stores, and convenience stores, and this makes up around 90% of our market. We did know this by this point.

In our panic to solve the problem, we tried to locate a mobile bottling company and the closest one that could package the bottle size we had on hand was located in the Northeast. The best way to describe their proximity to our brewery is to say they could have hit Newfoundland with a nine iron.

The two Bens at

Flying Heart will never know how much of a life saver they were during an

extremely critical time. The brewing community is full of good people, and the folks at

Flying Heart embodied that spirit in a time when we needed help most.

Seeing the Meheen run first-hand had us sold on its efficiency

and performance. We acted quickly to locate a bottling machine of our own, and Back Forty

Brewing out of Gadsen, Alabama was selling their Meheen. After some quick negotiations, we

elected to purchase their machine and have it shipped to Meheen HQ in Washington state for

some re-tooling and updates. It’s strange how you spend years planning,

vetting, and analyzing, but some things in business and in life you can’t really

prepare for, no matter how hard you try. Our packaging plan, which we’d debated

for nearly three years, was completely thrown out the window in a 72 hour

period. Pivot and move on. It is ok to throw up or punch a wall, too - that's what we do.

Just as our bottling woes were seeming to fade as we moved past the 4th of July, we were hit

with another punch to the brisket. Our brewer decided to relocate to North

Carolina and gave us his two week notice on July 30th.

We were in the first six months of expanding our

business, and we'd just got our bottling situation settled and then our most critical employee leaves with only a few weeks notice. (Notice I didn't say solved.) As one brewer once told me, "even the best bottling machines are a pain in the ass." As true and as poetic as Billy Shakespeare prose, in my experience. We'll explain that fun in more detail in a later post.

We

immediately - as in, within five minutes of receiving the notice - contacted our

brewhouse manufacturer, and fortunately we were able to locate and import a hired gun just two days after our previous brewer left. This allowed us to continue brewing beer for the immediate future and afforded us some much needed sleep after a few weeks of little of it.

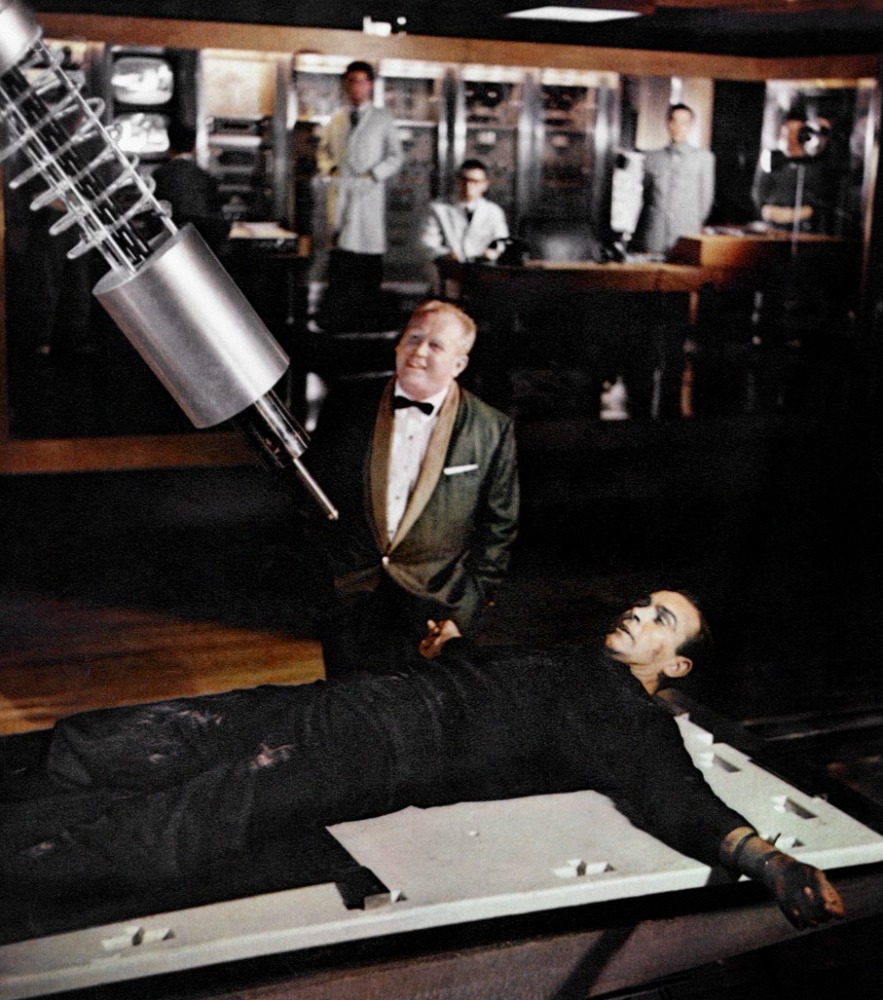

Imagine this guy as your savior...

No, I'm not kidding - that's actually him. And that's real Jesus hair. Not a wig.

Allen Sheppard, the blonde beauty shown above, was

really an angel when we needed it most. Red River Brewing moral was at an all-time low. We were without an experienced brewer, and we were still working through some major kinks on our packaging machine. What was worse, we didn't know what would happen when Allen had to leave to head to Germany in September. All that said, Allen wouldn't let us stay in the dumps for long. Literally, the

first day I picked Allen up from the airport, he insisted we drive straight to the brewery so he could get to work. This was on a Sunday, and he worked at our brewery tirelessly everyday until the Sunday he flew out of town.

Allen came to us with a great set of credentials. He had been

the head brewer at Edge Brewing in Barcelona, Spain. While there, Edge received the best new brewery by Rateabeer.com. Allen’s greatest assets are his

technical and mechanical skills, and he was invaluable trouble-shooting our equipment. Stuff breaks in a brewery pretty often...daily, actually. Meanwhile, we put out forum

posts, enlisted search firms, and networked with anyone who could actually pronounce reinheitsgebot in an attempt to locate a new full-time brewer. We had some of our homebrewing buddies come by and talk with us about the opening, and although we could have used the help, I was secretly more scared of having them quit their jobs and potentially dragging them into our nightmare.

In the end, Allen’s world-traveler status as a brewing consultant helped us locate our new

brewer. It only took a connection through a mutual contact in Singapore. That's all. The only problem,

Allen was to leave in mid-September for Germany for another gig, and our new beer-daddy couldn’t arrive until mid-November. Allen was a great mentor, friend, and story-teller who really "Shepparded" us through a dark a period in our company. It was a scary day when Allen left town, and I still remember the feeling leaving the airport after dropping him off. We were on our own from that point forward, without any real assurances that a steady brewer was going to join our team anytime soon.

As I write it this, it's hard to look back and realize all that happened between April and August 2016. These are just the high points, and there's actually a lot more of note that went on. It was certainly not in the plan we drew up, and there's really no play-book for how to deal with this stuff. We'd overcome so much, and yet there was still many unknowns for how we were to get our operations back on track, much less bridge the gap between Allen and our new brewer.

As for how we got through that brewer-less period, well, that is another story of heroics and for a different day and another beer or two for you, loyal reader...stay tuned for more.

Oh and thanks for drinking our beer. We only get to make more if people drink it. We like making beer, so thanks.